Thinking about using a fabric window seal kit to connect your portable air conditioner to a casement or awning window? You’re not alone. These kits are among the most common “quick fixes” sold online—often marketed as universal solutions with easy installation and fast Amazon delivery.

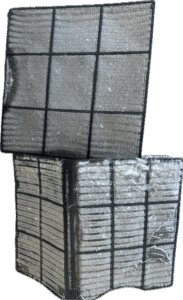

But here’s what we often see during installations: fabric kits like the HOOMEE tossed in a corner, adhesive residue left behind on window frames, and frustrated homeowners wondering why their portable AC isn’t cooling properly.

Let’s break down the main problems with a fabric window seal kit—and why a custom acrylic panel offers a far better long-term solution.

Why Fabric Window Seal Kits Fail for Portable ACs

❌ It’s a Temporary Fix, Not a Real Solution

Most fabric window seal kits are designed to zip around the AC hose and attach to the window frame using adhesive-backed Velcro. While this may seem convenient at first, the materials are thin, flimsy, and not built to withstand regular use. These setups typically start to fail within days or weeks—especially during hot weather.

🔥 Adhesive Fails in Heat

The adhesive used to secure the Velcro often melts or slips off when exposed to the hot exhaust air that builds up in the sealed window cavity. This results in loose seals, fallen kits, and glue residue left behind. It’s one of the most common issues we’re called in to fix.

💨 Hot Air Gets Sucked Back Inside

These kits are made of fabric, not rigid materials. That means the seal is never airtight. As your AC pulls air from inside the room (creating negative pressure), warm outdoor air is easily drawn back through the gaps in the fabric or around the zipper. This constant air seepage drastically reduces the cooling power of your portable AC and forces it to work harder—raising your energy bill and shortening the life of your unit.

🧵 Weak Zippers and Structural Sagging

Zippers used in these kits often jam or break after just a few uses—especially when exposed to sun, moisture, or frequent movement. Over time, the fabric sags or stretches, leading to gaping air leaks and a messy appearance.

😣 Poor Aesthetics

Let’s be honest—these kits aren’t pretty. From the inside, they resemble a wrinkled plastic bag taped to your window. From the outside, they can look cheap and unfinished. They’re not a permanent solution and often become an eyesore by mid-summer.

Why Custom Acrylic Panels Are a Better Option

If you want reliable, long-lasting performance from your portable AC—especially in casement, awning, or sliding windows—a custom-fit acrylic panel is the smarter choice.

✅ Key Advantages:

Rigid & Durable – won’t warp, sag, or tear over time

Clean & Professional Look – fits seamlessly into the window frame

Better Insulation – no fabric, no Velcro, no gaps

Heat & Weather Resistant – built to last for years

Reusable Season After Season – install it once and you’re done

At Aircon Rescue, we build and install panels that are made to measure for your window and your specific AC hose. No more failed seals, no more mess—just a clean, secure connection that helps your AC run efficiently.

Conclusion

While a fabric window seal kit may seem like a quick and cheap fix, the drawbacks often outweigh the benefits. From melting adhesive and air leaks to sagging fabric and poor sealing, these kits usually create more problems than they solve.

If you’re ready for a proper solution that performs well and looks great, consider investing in a custom acrylic panel. It’s the best way to get the most out of your portable AC without compromising on efficiency or appearance.

💡 Ready to Upgrade?

Get a quote for a custom acrylic window panel designed for your AC unit and window type.

👉 Request a Quote